Waters Corporation

UX Product Prototyping

Project Overview

The project redesigned liquid chromatography instruments using user feedback and cardboard prototypes to enhance usability, reduce downtime, and improve laboratory efficiency.

Skills UTILIZED

Product Usability Testing

In-Person Interaction Testing

Design Thinking

Personas

Cross-Functional Collaboration

International Experience

Project Details

Project Title: Waters Corporation Iterative UI Testing

Project Duration: 1.5 years

Project Overview:

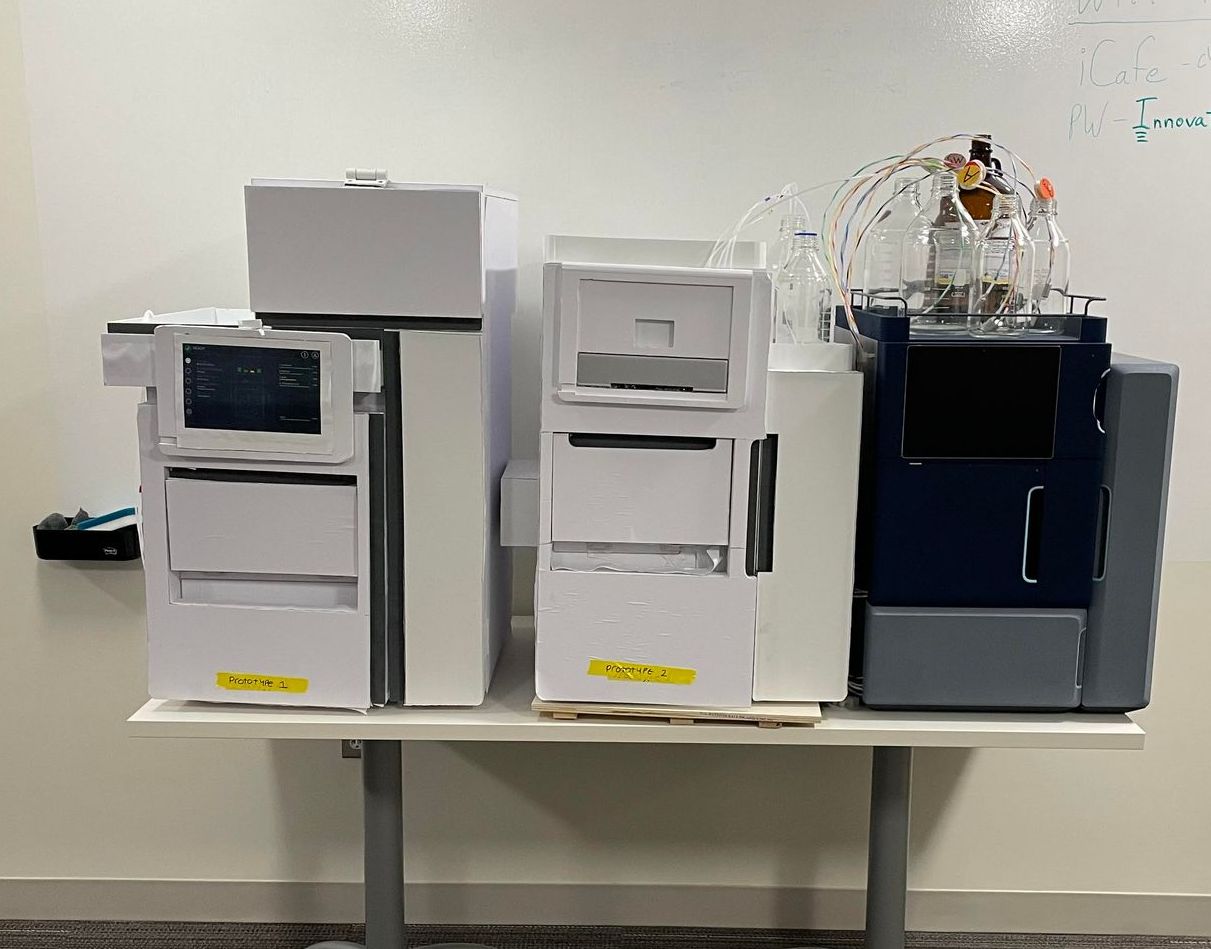

This project set out to redesign a Liquid Chromatography system. Through multiple rounds of research with experienced chemists from all around the world, we tested prototypes of a new system at different levels of fidelity, starting with cardboard boxes and finishing with a semi-functional, 3D-printed prototype.

Project Goals:

The primary goal of this project was to enhance the usability of liquid chromatography (LC) instruments by addressing inefficiencies and improving user experience through a complete redesign. The aim was to maintain the familiar aspects of existing systems while introducing innovative changes to optimize laboratory workflows.

Problem:

Users of existing LC instruments faced several issues, including awkward interactions, inefficiencies, and physical design flaws. Common problems included the need for stepstools to reach bottles, tangled tubing lines, and doors that required propping open. These challenges led to increased downtime, which in turn resulted in financial losses for laboratories due to disrupted workflows and maintenance needs.

Project Activities:

The project employed several methodologies to enhance liquid chromatography instruments. Initially, observations were conducted in a cutting-edge UX lab to identify common issues and inefficiencies with existing systems. This was followed by the development of two cardboard prototypes to explore different design solutions, focusing on aspects like door placement and bottle interactions. User testing involved gathering feedback from a diverse international group, including participants from North America, Canada, India, and China, both in the lab and on-site abroad. Additionally, a touch screen tablet was incorporated into the prototypes to assess potential improvements in user interaction.

Project Impact:

Through consistent testing and feedback incorporation, we developed a modern, "smartphone-like" user experience. The new UI reduced errors by providing useful notifications, simplifying tasks, and clarifying system statuses, thereby streamlining daily workflows for users.

High-Level Findings:

Overall, the redesigned prototypes successfully addressed the identified issues, leading to the development of a new generation of Waters Alliance LC machines. These machines are now in use globally, reflecting the project’s impact on improving laboratory efficiency and reducing operational costs.

- Users preferred more compact designs that saved valuable bench space in laboratories.

- Improvements were made to door interactions, making them more intuitive and user-friendly.

- Users express concerns about removable kiosk or hinged kiosk designs, not seeing the value in additional moving parts.

- Color-coded tubing lines were introduced to facilitate quick and easy identification, reducing confusion and errors.

- The addition of a touch screen tablet provided a positive user experience for interacting with the system.

Users valued compact designs not just for saving bench space, but for their ability to streamline workflows and reduce physical strain, highlighting how thoughtful design can transform both efficiency and comfort in the lab.